|

NEWS September 2020 |

| Si vous ne recevez pas correctement ce message : cliquez ici | ||

|

||

|

| Installation and Integration of an Oxyfuel Combustion Engine System with CO2 Capture and Storage Facilities on a Ship |

| written by Jens Ley and Klaus Bieker, Department Design and Simulation of Ships and Offshore-Structures, Development Centre for Ship Technology and Transport Systems e. V. Oststraße 77, 47057 Duisburg, Germany |

|

Objective |

|

Narrowboat and Integration Concept |

|

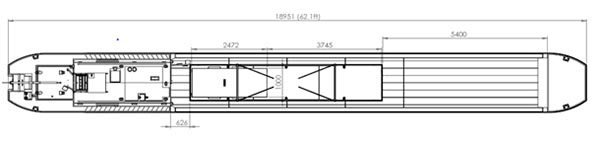

| Figure 1: Principle sketch of the narrowboat, Source: CRT |

|

To run the oxyfuel system with 7.5 l gasoil, the following requirements have been identified beforehand: |

|

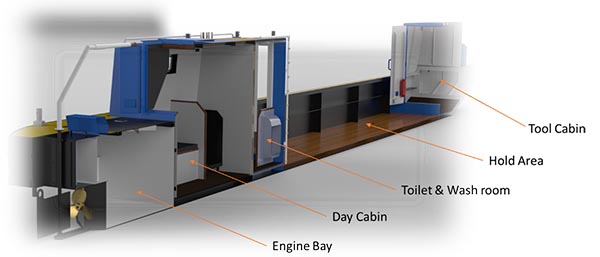

| Figure 2: Room arrangement, Source: CRT |

|

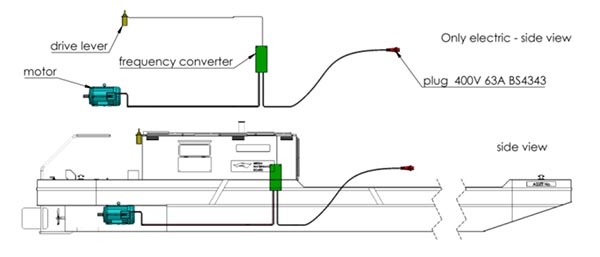

| Figure 3: Principle arrangement of the electric system in the narrowboat, Source: DST |

|

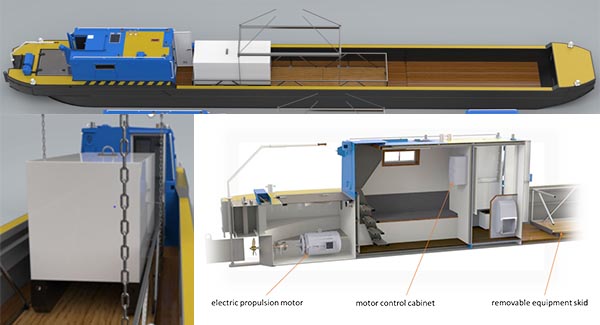

The space demanding Oxyfuel engine and CCS is placed in the cargo hold of the ship on a dedicated removable skid, see Figure 4. To maintain enough cargo hold space a project specific vessel was designed by CRT with an increased length of 18.95m (instead of 16.05 m common for 130 Class F vessels). In addition, mounting the project equipment on a skid was found to be advantageous as the equipment can stay connected to the skid when the trial runs are finished. It will be ready for re-use. The required Oxygen bottles and CO2 storage tank will also be placed on the skid. |

|

| Figure 4: Usage of cargo hold for the skid and generator set, (top) side view and (bottom left) perspective view from the front, (bottom right) view into the engine bay and cabin, Source: CRT |

|

The construction of the vessel started in March 2020 and will be completed by July 2020 ready to accommodate the skid and commence ‘on water’ trials. |

|

Development Centre for Ship Technology and Transport Systems e. V. (DST) |

|

| Figure 5: Development Centre for Ship Technology and Transport Systems in Duisburg, Germany, © DST |

|

Key business elements of DST are the investigation of the special flow conditions of ships in inland and coastal waters with restricted depths and the support of the inland navigation sector in the development and modernization of vessels. Within the last couple of years, the environmental performance of IWT has moved into focus and resulted in many projects for the holistic greening of the fleet. Furthermore, issues of transport engineering and logistics as well as transport economics are in focus with the objective to access new potential of inland navigation and thus contribute to economic and ecological approaches to meet the increasing demand for transport. In addition, port management concepts and modern transshipment solutions belong to the scope of the DST. Since 2008 the DST operates a ship handling simulator, called SANDRA. In addition to use in research projects, the education and training of crew members in the simulator is becoming more important. |

|

| Figure 6: Shallow water tank facility at DST, © DST |

|

The main contribution of DST in the RIVER-project is the integration of the newly developed oxyfuel combustion and CCS system into a small inland waterway vessel. For the ship, suitable basic system configurations were investigated and compared with a common diesel engine approach in terms of required tank capacities (additional weights and volumes), fuel consumptions and mechanical power distribution. Another task is the elaboration of a feasibility study for a conventional large inland cargo vessel. DST is also responsible for the identification of technical and financial barriers of the newly developed technology. |

| Conformément à l'article 34 de la loi 78-17 du 6 janvier 1978 relative à l'informatique, aux fichiers et aux libertés, vous disposez d'un droit d'accès, de rectification des données nominatives vous concernant. Si vous ne souhaitez plus recevoir aucun message électronique de la part de Critt : cliquez ici |