|

NEWS September 2019 |

| Si vous ne recevez pas correctement ce message : cliquez ici | ||

|

||

|

| Investigation of Oxyfuel Combustion on Engine Performance and Emissions in a DI Diesel Engine | |||||||||||||||||||||||||

| By Raouf Mobasheri & Abdel Aitouche & Boualem Bakir Department of Energies, Electricity and Automatic, CRIStAl-HEI – Yncréa HdF, 13 rue de Toul 59046 Lille Cedex, France |

|||||||||||||||||||||||||

| Main Objective | |||||||||||||||||||||||||

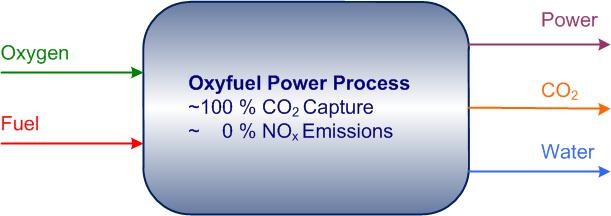

| Due to stronger environmental standard aims, the European Union (EU) has recently adopted more stringent limits for emissions from inland waterway transport (IWT). The main objective of project RIVER for which this reported work is relating is to investigate and develop possible low-carbon or non-carbon solutions for inland waterway vessels. For this purpose, RIVER has employed oxyfuel combustion coupled with Carbon Capture and Storage (CCS) technology to achieve nitrogen-free combustion and zero-carbon emissions. | |||||||||||||||||||||||||

| Oxyfuel Advantages & Disadvantages | |||||||||||||||||||||||||

| Using oxyfuel combustion enables the increasingly expensive and complicated NOx after-treatment systems to be completely eliminated. It also offers good fuel economy and very low levels of particulate emissions. However, using pure oxygen instead of air, will accelerate the combustion process. With the heat release rate dramatically increased, it takes much shorter time to complete the entire heat release process. With such a high heat release rate, the flame temperature is expected to increase by around 500-800K. This necessitate a set of countermeasures to avoid overheating problems. | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Simulation Study and Analysis | |||||||||||||||||||||||||

| As part of the RIVER project, a CFD simulation has been carried out to evaluate the influence of oxyfuel combustion on engine operating conditions and combustion characteristic in a High Speed Direct Injection (HSDI) diesel engine under LTC mode. Four diluent strategies based on the volume fraction of O_2 and a diluent gas (CO_2) has been considered. A High-Speed Direct Injection (HSDI) Ford Puma common-rail diesel engine is used in this study. | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Investigations have conducted using four different diluent strategies based on the volume fraction of O2 and a diluent gas (CO2). The O2 concentration in the intake was varied between 17% and 23% by volume. | |||||||||||||||||||||||||

| Simulation Achievements | |||||||||||||||||||||||||

| The research is yet to enter the experimental testing stage. Nevertheless, CFD results and preliminary simulation data discussed in this paper have suggested that the oxyfuel HCCI combustion has potentials to bring PM and CO emissions to a very ultra-low level while the NOx emissions can be completely eliminated. | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

The major results of this study can be summarized as follows : • By increasing O2 concentration from 17% to 23%, the ignition period is shortened and fuel is burned more rapidly which results in a higher in-cylinder temperature and in-cylinder pressure. • By increasing the diluent ratio at low engine loads the amount of fuel consumption is largely increased while it doesn’t bring any remarkable change at high engine loads. • The increase of diluent ratio from 77 to 83 vol.% under constant fueling rate does not bring any remarkable change to engine power at high engine loads. However, by decreasing the fuel rate, the difference between different diluent strategies become more obvious as the minimum amount of engine power is achieved when 83 vol.% of CO2 is used in the intake charge. |

|||||||||||||||||||||||||

| Technical and Steering Committee Meetings in Luton | |||||||||||||||||||||||||

|

The technical and the steering committee was held in 20th and 21st June 2019. During the meetings, these subjects were discussed: • River’s Project Progress • Technical information- Narrowboat Diesel Electric Propulsion • Actual Engine Tesbed • Simulation of Oxyfuel combustion on Engine (see article above) • CO2 transformation • Deliverables done for Period 3.1 and expected in Period 3.2 • Financial status • Communications |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

Next Technical and Steering Committee Meetings The next meeting will take place in Luxemburg on 12th December 2019 at the CleanCarb Company. Peter Dooley will prepare the agenda in collaboration with the lead partner and he will prepare the invitation letter for partners. |

|||||||||||||||||||||||||

| University of Bedfordshire (UoB) | |||||||||||||||||||||||||

| UoB is among the most successful new universities in the UK; innovative, enterprising and business-facing, with a flourishing student community of over 22 000 students from over 100 countries. It is one of top 10 Universities in UK for providing the student experience (NSS 2014 and 2015). Almost half of research carried out by academics at the University of Bedfordshire is rated as World Leading or Internationally Excellent (REF 2014). In 2013 UoB has received Queens Anniversary Prize for Pionee. | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

Main role in RIVER project In RIVER project, the University of Bedfordshire will mainly be responsible to develop the after-treatment systems and applying the CCS (Carbon Capture and Storage) technology using the exhaust gas heat exchanger, water/gas separator, CO2 compressor, CO2 tanks and etc. |

|||||||||||||||||||||||||

| Conformément à l'article 34 de la loi 78-17 du 6 janvier 1978 relative à l'informatique, aux fichiers et aux libertés, vous disposez d'un droit d'accès, de rectification des données nominatives vous concernant. Si vous ne souhaitez plus recevoir aucun message électronique de la part de Normandigital : cliquez ici |

|||||||||||||||||||||||||